DRIVER-FACE-DESIGN

Don't overlook driver-face- design in choosing your head

Your driver-face-design is a combination of its size, curvatures, material, thickness and any variation in the thickness over its area to create a difference in the amount the face deflects or flexes in response to the impact with a golf ball for any loft. The face design of a driver didn’t become a factor to consider until hollow metal woods replaced solid ones

When you hit a golf ball, because the ball is of a more resilient material and its mass is so much smaller than the face of the driver, it is responsible for up to 80% of the loss of energy between the two. As a result, during a typical drive, the ball will compress in diameter against the face, and cause a greater energy loss than the amount that the face of the head may lose when its face flexes inward. Thus, if the driver face design can be made so it deflects more, the golf ball will compress less and the result is more ball speed velocity in relation to the golfers swing speed. This is what is referred to as “Smash Factor”. The smash factor is the ratio between ball speed and club head speed.

An in depth explanation can be found elsewhere on our website. For now, an increase of 1 mph of ball velocity will translate into a carry distance of 1.8 yards.

But driver-face-design is not only about creating the maximum deflection of the face to achieve the highest possible ratio of ball speed to clubhead speed. It is also important for a good face design to generate the most deflection possible when the point of impact is not in the center of the face. Something we mere amateurs do a lot more often than the pros. In the design of a driver’s face, factors that influence the loss of face deflection from an off-center hit are:

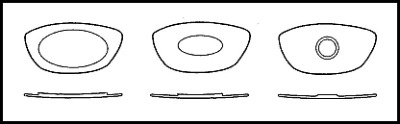

1. The shape of the face: Face shapes which are both larger overall and closer to being round like a circle can help reduce the loss in face deflection from an off-center hit.

2. Variable thickness faces: Faces that are slightly thicker in the center and thinner all around the outer perimeter “spread out” the area of close to maximum deflection so that impacts which are up to ½” off-center will not lose more than 3-4 mph of ball velocity.

3. The face material: the greater the ratio of strength to elasticity of the material from which the face is formed, the greater the potential for deflection.

4. Loft Angle: the lower the loft angle on the face, the more the face will deflect for any given impact speed and face thickness for a specific material.

5. Impact Speed: the greater the clubhead speed at impact with the ball, the more the face will deflect.

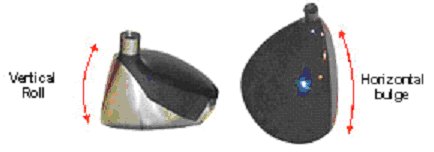

6. Bulge and Roll: the less curvature on the face, the more the face will deflect. Go to the Bulge and Roll page

Driver-face-design, in the past, was definitely a factor with wooden (persimmon) and metal (stainless steel) heads, but now with the USGA enacting a series of new rules pertaining to the performance of golf equipment that are specific to limiting the distance the new spring-faced titanium driver heads will hit the ball, ie: COR and Characteristic Time, it is unlikely that face design with the driver will bring about a large increase in distance. However, one should take note of any Titanium heads with specific variable thickness and roll specs that will help increase the ball velocity